The global auto industry is on the road to recovery, with gains anticipated in all regions except Europe, according to Polk, a leading global automotive market intelligence firm. Worldwide new vehicle sales in 2012 are expected to rise 6.7% over 2011 volumes. China’s sales growth is forecast to grow 16% over 2011. The US market will increase 7.3% to 13.7 million vehicles, say Polk analysts, who do not expect the US to achieve pre-recession levels of greater than 16 million units per year until 2015. European sales are expected to be flat or down slightly in 2012.

Automakers are feeling confident that the worst is over, as evidenced in January at the North American International Auto Show (NAIAS) in Detroit. More than 40 vehicle debuts were featured at the show, offering abundant choices for consumers. Fuel economy has become more important than ever – which can only be good for lightweight composites. Vehicle manufacturers know they need to examine every component and system on their vehicles to meet higher government fuel efficiency standards. In the US, the government will require a corporate average fuel efficiency increase equivalent to 54.5 miles per gallon (23.17 km per litre or 4.32 litres per 100 km) by 2025. Estimates put the amount of weight that needs to be shed from a typical vehicle at upwards of 540 lbs (245 kg) to attain that target.

As a result, automotive tier suppliers are working overtime to develop more efficient processing techniques and shorter cycle times to produce components for cars and trucks at high production rates. Meanwhile, scientists continue working on ways to bring down the cost of carbon fibre reinforced plastic (CFRP) composites.

Automotive FRP market

According to market research firm Lucintel, the global automotive fibre reinforced plastic (FRP) composite materials market is expected to reach US$3.7 billion by 2016, up from $2.4 billion in 2010, at a compound annual growth rate (CAGR) of about 8%. Demand for weight reduction, fuel efficiency and reduced emissions will drive the use of composites in the automotive industry, says Lucintel. While noting that carbon fibre usage would remain limited to high-end and premium segment cars, the researchers acknowledged that the advent of lower cost and performance (than aerospace) CFRP could open a new era for advanced composites in high-volume applications.

Thermosets have long been used to mould strong, lightweight structural components for vehicles. More recently, thermoplastics have been making inroads due to their suitability for rapid production and recyclability. The Automotive Composites Alliance (ACA), an arm of the American Composites Manufacturers Association (ACMA), recently announced that it has expanded its scope beyond thermosets to include the thermoplastics side of automotive composites.

The increased demand for vehicle lightweighting could significantly change the composite automotive market, relates the ACA, which has historically served as an advocate for thermoset composites moulders and suppliers. The move changes the ACA to a market-focused alliance based on all potential composites applications, not just a materials alliance. The association is currently seeking automotive industry representatives to become involved with ACA activities.

Manufacturing technology company Fiberforge has installed its first Relay Station in Europe at the Fraunhofer Institute for Chemical Technology (ICT) in Pfinztal, Germany. The Relay Station 2000, the largest in the world, will be used at Fraunhofer ICT to conduct R&D projects for various industries, including automotive. The equipment creates tailored multi-ply preforms from unidirectional thermoplastic prepreg tapes that are pressed into parts.

The ICT recently announced that its engineers have developed a thermoplastic resin transfer moulding (RTM) process that cuts the manufacturing cycle time to about 5 minutes and makes it possible to manufacture up to 100 000 FRP parts per year. In the process, a pre-heated textile structure is inserted into a thermostatically controlled moulding tool and resin is injected. By controlling temperature during the processing stage, the cycle time can be reduced significantly, according to the ICT. A trunk liner for the Porsche Carrera 4 moulded using this process weighs 50% less than its aluminium counterpart and is said to have improved the car’s overall structure in terms of crash behaviour.

Move toward carbon fibres

The number of automakers turning to carbon fibre composites to save weight continues to rise. The BMW i3 (Megacity Vehicle), to roll off the assembly line in 2013, will be the first high-volume production vehicle with extensive CFRP components, including the passenger cell. The battery-powered vehicle will be built in Germany at the rate of 40 000 units per year. The BMW i8, a CRFP-intensive sports car with electric-hybrid drive, will be rolled out later. SGL Automotive Carbon Fibers, a joint venture of SGL Group and BMW, was established to supply non-crimp carbon fibre fabrics for the new BMW models. Two plants, one in Washington state, USA, and another in Wackersdorf, Germany, will start supplying carbon fibre materials next year, according to the manufacturer. The two plants will have an initial capacity of 3000 tonnes.

Another joint venture, between SGL and Mitsubishi Rayon Company, has been established to supply PAN-based precursor to produce the carbon fibres.

General Motors and Tokyo-based carbon fibre supplier Teijin Ltd announced in December that they will partner to co-develop advanced carbon fibre composite technologies for potential high-volume use globally in GM vehicles. Teijin plans to open a US technical centre to facilitate collaborative development. The company has developed technology to produce thermoplastic CFRP components in a press forming process with cycle times of under a minute. Last year Teijin produced an electric vehicle concept car from CFRP that weighed only 47 kg (103.6 lb).

GM’s new relationship with Teijin “provides the opportunity to revolutionize the way carbon fibre is used in the automotive industry,” relates GM Vice Chairman Steve Girsky. “This technology holds the potential to be an industry game-changer and demonstrates GM’s long-standing commitment to innovation,” he adds.

The partnership is expected to play an important role in GM’s initiative to bring CFRP into mainstream vehicles.

Audi AG and Voith GmbH have formed a development partnership for the commercialisation of lightweight fibre-reinforced materials, including carbon fibre, in automated high-volume production for automotive applications. Audi already possesses solid experience in lightweight construction. Weight and strength advantages offered by advanced composites have been demonstrated in the Audi R8 and Audi RS3, among other models.

One focus of the partnership with Voith will be to utilise the great potential of fibre-reinforced materials for innovative automotive architecture, says the automaker. Audi promotes development of composites at its Neckarsulm site in Germany in a technical research unit for fibre-reinforced polymers connected to its Lightweight Design Center. Fibre-composite polymers will continue to gain importance in the material mix of the automobile, relates Audi.

Quickstep Holdings has teamed up with Audi and the German government to develop lower-cost composites for automotive applications in the PRESCHE Project. A target of 30% reduction in cost for lightweight composites has been set in the project, which incorporates Quickstep’s out-of-autoclave process, using heat transfer fluid to rapidly cure advanced composites, and the company’s robotic Resin Spray Transfer (RST) technology to produce high-volume auto parts.

Dollars for R&D projects

The automobile industry has the potential to become the largest market for carbon fibre composites, but only if the cost of the material can be brought down substantially. Last summer, the US Department of Energy (DOE) awarded US$175 million to support projects related to advanced vehicle R&D, including development of lighter-weight materials with a goal of improving the fuel efficiency of next-generation of vehicles.

Among those receiving awards was Zoltek Companies, winning $3.7 million to develop a novel, low-cost route to producing high-performance, low-cost carbon fibre using a lignin/PAN hybrid precursor and carbon fibre conversion technologies. Zoltek has been working with Weyerhaeuser Company for nearly two years to develop the hybrid precursor. Combining precursor technology with improvements in operating and energy efficiencies for carbon conversion is expected to provide lower-cost carbon fibre for automotive and applications. Zoltek recently started producing prepreg materials for automotive components.

The United States Automotive Materials Partnership was awarded $3.5 million for a project to validate crash models for carbon-fibre composites that would enable the use of lightweight composites in primary-structural automotive crash and energy management applications. In addition, Plasan Carbon Composites was awarded $2.5 million for a project to evaluate and validate models for predicting crash behavior of carbon fibre composites by building and testing subcomponent structures.

Others received DOE awards for a demonstration project for a multi-material, light-weight prototype vehicle as part of the Clean Energy Dialogue with Canada. Vehma International of America was awarded US $10 million to develop and validate a “new passenger vehicle design architecture” which facilitates a 50% weight reduction through the extensive use of lightweight and high-strength materials. Another $10 million award went to Chrysler Group to develop and demonstrate a vehicle incorporating technologies targeting 50% weight reduction.

Innovative applications

Sabic Innovative Plastics has opened a speciality polypropylene (PP) compounding operation at its Mississippi, USA, plant to supply SABIC® PP and STAMAX® long glass fibre-filled (LGF) PP in response to growing demand from automotive OEMs, the company reports. PP materials have been growing at the rate of 3-5% annually, replacing metals and other polymers in a range of components, notes SABIC.

The company’s products were recognised at the 2011 Society of Plastics Engineers (SPE) Automotive Innovation Awards competition in Detroit in November. STAMAX 20% LGF PP and 30% talc-filled PP is used by Faurecia along with Trexel MuCell microcellular foam injection moulding technology to produce the instrument panel in the 2012 Ford Escape/Kuga. The first instrument panel and largest component ever moulded using this technology was judged the Grand Award winner. Benefits include weight reduction, plus cycle time reduction of 15%, machine clamp tonnage reduction of 45% and an estimated US$3 savings versus solid injection moulding.

The SPE Hall of Fame Award went to SuperPlug, an all-plastic structural door-hardware module produced by Inteva Products, formerly Delphi Interior & Lighting Systems. SABIC’s Xenoy® 30% glass-filled polycarbonate (PC)/polybutylene terephthalate (PBT) resin is used to injection mould the module, which has been used since 1997 on over 60 million GM vehicles worldwide. The door module, which replaced 40 separate metal parts, reduced costs by 10%, reduced weight by 3.3 lb (1.5 kg) per door and simplified assembly.

The SPE Innovation Award for the Most Innovative Use of Plastics in the Body Exterior category went to an injection moulded storage bin with twin-sheet thermoformed lid for Chrysler Group’s 2012 Ram pickup. Ashai Kasei Plastics North America developed two new UV-resistant grades of Thermylene® short-glass-reinforced polypropylene for the lockable RamBox® storage system. The resin enabled processor Penda Corp to thermoform the lid rather than blow mould it, as was done on the first generation lid, creating a stiff yet lightweight part at lower tooling and processing costs.

A prototype of a structural composite automotive underbody is being tested by the Automotive Composites Consortium of the US Council for Automotive Research (USCAR). Designed and fabricated for high-volume, mid-size production cars, the large, multi-layered component was compression moulded of glass/vinyl ester sheet moulding compound (SMC) with additional chopped glass reinforcement and a high-elongation fabric sandwiched between glass fabric layers. Designed to absorb or transfer dynamic external crash forces, the patented component could replace up to 17 steel parts and reduce a typical passenger car’s weight by 25 lbs (11.3 kg), according to USCAR. A paper on the multi-year project won the Best Paper Award at the 2011 SPE Automotive Composites Convention & Exhibition (ACCE) in September.

EV and hybrid technology

The lithium ion battery pack in the Chevrolet Volt hybrid car won an Innovation Award in the Powertrain category at the 2011 Society of Plastics Engineers (SPE) Automotive Innovation Awards competition in Detroit in November. The 135 battery module frames in each battery pack are injection moulded of BASF’s Ultramid 1503-2F PA 66 (33% glass-filled) by Mann+Hummel. The frames are an integral part of the electric vehicle (EV)’s thermal management system, channelling coolant to and from the cells. The hydrolysis-resistant Ultramid composite provides the exacting consistency and levels of repeatability and reproducibility required by this application, noted SPE’s panel of judges.

A UK project to develop a lightweight, extended-range electric-hybrid commercial fleet vehicle is now in the technology demonstrator stage, report collaborating partners Revolve Technologies Ltd and IE-LEV Ltd. Composite body panels are produced using epoxy prepregs from Advanced Composites Group (ACG), a key development partner in the project. Codenamed the t-001, the vehicle is expected to significantly reduce fuel costs. A vinyl wrap system will replace paint.

ACG prepregs are also being used to produce the bodywork of the Spano super sports car by Spanish automaker GTA Motor. ACG’s BPS240 body panel system is a two-ply partially impregnated epoxy prepreg system specifically designed for the manufacture of body panels using vacuum bag processing. Tooling for the Spano’s panels was made using ACG’s LTM® tooling prepreg. Interior and exterior trim are moulded using ACG prepregs.

A new concept EV developed jointly by smart and BASF, the smart forvision, showcases technologies incorporating energy efficiency and lightweight design, including the first all-plastic wheel concept with potential for volume production. Made from BASF’s impact-resistant specialty polyamide (PA) Ultramid® Structure, the wheel weighs about 3 kg (6.6 lb), 30% lighter than a conventional aluminium wheel. In addition to other future-looking technologies, the smart concept also features carbon fibre/epoxy composite doors and body cage for additional weight savings.

Toray recently introduced a next-generation concept EV, the TEEWAVE AR1, short for Toray Eco Efficient Wave Advanced Roadster 1. A monocoque body and innovative energy absorber system are produced using RTM CFRP thermoset composites. Thermoplastics were used to produce other CFRP parts in a one-minute process. The roadster weighs 846 kg (1865 lb), including the 220 kg (485 lb) battery pack, and has a range of 185 km (115 miles) before recharging is necessary.

A lightweight DeLorean electric vehicle will go into production this year. The body made of resin infused advanced composites achieves a weight reduction of 200 lb (91 kg) over the original body structure, the company notes. Original DeLorean cars, produced in the 1980s, can be retrofitted with the new composite body.

Also new is a three-wheeled Kobot, a carbon fibre intensive EV which was introduced at the Tokyo Motor Show in December.

Exotics and concepts

A unique, high-powered sports car heading for production next year is the Donkervoort GTO, which weighs only about 700 kg (1543 lb), thanks to CFRP panels and structural components, as well as lightweight engine technology. The composite panels are bonded to a steel tubular frame, producing exceptional rigidity, Dutch automaker Donkervoort relates.

Production is also scheduled in 2013 for Lamborghini’s Sesto Elemento, which sports extensive use of CFRP composites (body weighs just under 1000 kg/2205 lb). However, the premium automaker plans to make only 20 units, and those strictly for the race track.

Falcon Motorsports of Michigan chose the NAIAS venue to introduce its F7 supercar, sporting carbon fibre interior and exterior panels on an aluminium chassis with an integrated carbon fibre structural tunnel, floor pan and firewall. The F7 is powered by a 7-litre V-8 aluminium engine producing 620 hp. The company expects to produce 10 cars per year.

New material innovations

Henkel AG has developed a new composite matrix resin based on polyurethane that is said to enable improved economics and throughput in processing compared to standard epoxy matrix resins. Loctite MAX2 is said to cure significantly faster and offer more efficient impregnation in resin transfer moulding (RTM) processing without stressing the fibres due to the lower viscosity of the resin. The company relates that the new resin is well-suited for high-volume automotive components.

|

Innovation and fresh ideas in composites for automotive applications are coming from the bottom up – from small, independent companies – not from the top down, says Nathan Armstrong, president and director of Motive Industries in Alberta, Canada. The company has developed the Kestrel, a biocomposites-intensive EV that is targeted for commercial introduction this year. “The small guys now have the same tools as the big guys, but often with more freedom and flexibility to demonstrate applications in technology that the large companies cannot. The impact this has had on industry is unquestionably enabling the largest shift in influence ever seen,” said Armstrong, speaking before a record crowd at the SPE Automotive Composites Conference & Exposition in September in Michigan. He observed that the technology available to the small automaker of today includes advanced computer-aided design technology, rapid prototyping machines capable of printing useable parts, CNC mills with up to 6 axis that allow nearly any shape to be cut, polymers that can be moulded at room temperature using silicone moulds and composite materials that exhibit extremely high strength properties. Small manufacturers have the knowledge and experience needed to combine all of these elements into what he calls the “second industrial revolution.” Armstrong believes that “with this freedom of design and access to advanced materials such as FRP materials, the feasibility of the small automaker re-emerges. By using composites and plastics, tooling costs to produce vehicles drop drastically and performance can be accurately determined before any production begins. Also, with the dramatic increase in strength and durability that composites bring vs. metals, the safety level of these vehicles can be increased, eliminating any fears over liability,” he related. |

Milliken has developed Hyperform® HPR-803i synthetic mineral reinforcing fibres to replace other fillers such as talc in filled PP compounds. Benefits include weight savings, improved stiffness and excellent surface quality, according to the manufacturer. Milliken has targeted an array of automotive applications for the new product, from exterior panels and under-hood components to interior applications. Scratch depth and visibility are said to be improved by the new reinforcing agent, as well as colourability and appearance.

Ford Motor Company is using fibres from the kenaf plant in a PP matrix (50:50 ratio) to produce interior door bolsters for its new Escape sports utility vehicle, reducing the weight of the components by 25%. The use of kenaf in this application will offset 150 tons of oil-based materials per year, says Ford.

Dow Automotive Systems has announced a new grade of its epoxy-based Voraforce™ Composite System specifically for CFRP, offering fast cure rates in RTM with carbon fibre materials. Exceptional thermo-mechanical properties and excellent compatibility with carbon fibres characterise the new Voraforce epoxy-based solutions, says Dow. The absence of styrene emissions during fabrication and low volatile organic compounds (VOCs) are among the advantages offered by the entire Voraforce Composite Systems range, the company adds.

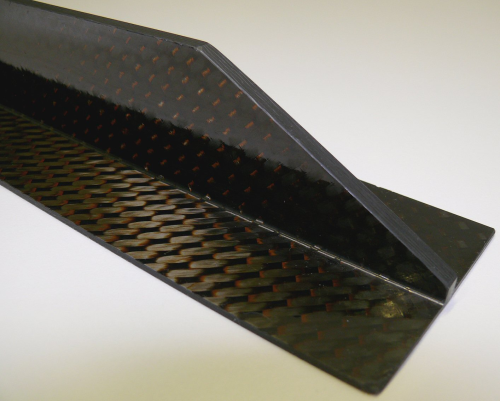

Recycled carbon fibre is also making headway. Low-cost blended carbon fibre yarns and fabrics have been developed by a multi-partner UK project called Fibrecycle. With funding support from the Technology Strategy Board, the four-year-old research project has focused on blending carbon fibre and PET (50:50 weight ratio) to produce yarns from virgin carbon fibres recovered from waste streams.

The partnership, which includes Advanced Composites Group (ACG), has reportedly made excellent progress toward its objectives of developing low-cost, high-performance carbon fibre materials to enable the production of technical fabric for the composites industry. The co-mingled carbon fibre yarns and fabrics are said to be suitable for many applications in the automotive and other sectors.

Under the hood

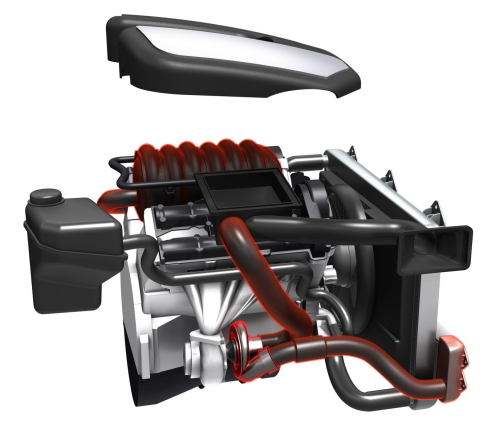

Composites continue to replace metals in new applications in the engine compartment, where temperatures can exceed 200°C. One example is Ford Motor Company’s new turbocharged EcoBoost engine, which uses high-temperature thermoplastic composites for a wide range of components, including engine and cam covers, ducts and hoses. Lightweight materials help get improved performance, including better fuel economy from a smaller, lighter engine, says Ford.

DuPont Engineering Plastics has developed Zytel® Plus polyamide (PP) 66 grades, with glass fibre loadings ranging from 30% to 50%, specifically for under-hood applications. They offer an ability to withstand long-term exposure to heat and chemicals better than traditional nylons. That is due to DuPont™ Shield technology, which combines several innovations, including a new polymer backbone, polymer modifications and additives to enhance performance characteristics, relates DuPont. In many cases, Zytel Plus can double the life of thermoplastic components exposed to hot, chemically aggressive and humid environments, the manufacturer adds.

BASF recently introduced a new grade of Ultramid® Endure polyamide with 50% glass fibre content for metal replacement opportunities in the engine compartment. Endure D3G10 is said to offer excellent stiffness at elevated temperatures – heat aging up to 220°C with a tensile modulus of more than 17 000 MPa after aging, making it suitable for use in charge air systems, according to BASF. Compared to high-priced specialty polyamides, the use of Ultramid Endure can produce a significant system cost reduction.

|

The Oak Ridge National Laboratory (ORNL), which is managed for the US Department of Energy in Oak Ridge, Tennessee, continues to explore the use of low-cost carbon fibre composite materials for automotive production. ORNL relates that it is aggressively researching less expensive alternative precursors, advanced technologies for converting conventional and alternative precursors to carbon fibre, and low-cost composite design and manufacturing capabilities. Lowering the cost of carbon fibre materials is a challenge because of the of the high cost of carbon precursors, the expensive energy and equipment required, and the cost associated with a limited production rate, explains ORNL. Carbon and graphite fibres are conventionally produced through the controlled pyrolysis of fibrous organic carbon precursors such as polyacrylonitrile (PAN), mesophase pitch (petroleum or coal tar), rayon, or other polymeric-based precursors in a lengthy process. ORNL recently announced that researchers are currently working with a microwave-assisted plasma (MAP) system developed at the lab to produce carbon fibres with specific mechanical properties on a continuous or semi-continuous basis more efficiently and less expensively than conventional methods. According to ORNL, this invention can contribute to widespread use of carbon fibre-based composites in automobiles. The MAP system simplifies carbon fibre production by replacing the conventional carbonisation, graphitisation and surface treatment process steps with a single MAP processing step. The combined use of microwave and plasma energy allows the system to operate at a low thermal inertial (low mass) in less time and with less energy than conventional processes, says ORNL. |

Hollow fluid carrying tubes for use in the engine compartment are being produced in high volumes by Teklas from BASF’s special Utramid® A3HG6 glass fibre reinforced PA 66 grade. The material, developed specifically for water-assisted injection moulding (WIT), is said to provide smooth inside and outside surfaces and high chemical resistance. The tubes are used to carry cooling water, air and oil.

Arkema recently introduced a high-heat-resistant, flexible PPA-based polymer, Rilsan® HT, to replace metal for flexible pipes and tubes in the engine compartment. The new material offers processing versatility – able to be injection moulded, extruded, thermoformed and injection blow moulded – and is compatible with other high-performance polyamides and PPA. Rilsan HT also offers cost advantages that can lower overall system costs by up to 50%, says Arkema.

A. Schulman has developed customised high-performance compounds for extruding smooth and corrugated tubing structures for fuel and brake lines in the Schulamid® line of engineered plastics for fluid management systems. Schulamid Nylon 612 products offer high dimensional stability (via low moisture absorption), chemical and corrosion resistance, high heat resistance and cold temperature impact resistance, the company reports. ♦

This article was published in the March/April 2012 issue of Reinforced Plastics magazine.