Ahlstrom's new production plant for glass tissue in Russia will start operations early next year. This follows on from the start up of a new speciality reinforcements plant in the USA late ast year. These two major investments in the Glass Nonwovens business in key areas of the world are visible evidence of the Ahlstrom Group's global growth strategy.

Over 90% of the Glass Nonwovens business' sales were in Europe in 2006, where it has two production facilities in Finland. With the US plant it can now supply North and South American and other US$-based locations. With the Russian plant, the business establishes a foothold in this important emerging market.

New regions

The 11 000 m2 US plant is located at a facility in Bishopsville, South Carolina, which it shares with Ahlstrom Filtration. The result of a €10.2 million investment, it is a copy of the Mikkeli speciality reinforcements plant in Finland and will convert glass fibre into specialised fabric products.

The start up of the US plant was very quick, according Wayne Merrit, General Manager, Specialty Reinforcements, at the Bishopsville facility. The plant currently employs 62 people but he says he is still adding to this.

The plant's production will primarily serve the marine, wind energy and transportation markets, which Ahlstrom sees as the highest growth areas for composites, showing an above average increase over other applications.

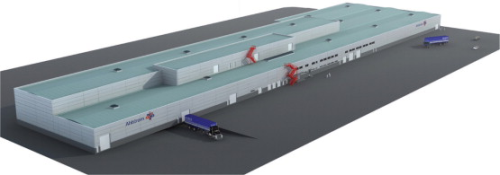

The Russian plant will produce glass fibre tissue, which is used as surfacing veil in the composites industry, and mainly in the building and construction industries where applications include vinyl flooring, building panels and roofing. The €38 million greenfield plant is in Redkino, in the Tver, area, about 120 km North West of Moscow. Although it will initially produce 4 m wide tissue, space has been reserved for a converting operation in the future, and there is room for further expansion. The tissue plant is expected to employ around 70 people when fully operational.

The plant's initial production will focus on serving the country's fast growing building and renovation industries, and on supporting Ahlstrom's Russian customers.

Ahlstrom has developed strong links with the emerging Russian composites market. It is important to have a production facility in Russia since products coming in from Europe face big import duties, notes Jönsas.

The Russian production plant will primarily serve the growing domestic market, but it can also supply Europe, and also Asia if needed, he says, as the facility is logistically well located.

As with all companies aspiring to be global players, Ahlstrom is also looking at opportunities in China and India. The group already has a plant in China, currently producing filtration products, and it has purchased land in India. Announcing the signing of a Memorandum of Understanding with Mundra Special Economic Zone in Gujarat this May, Ahlstrom said the purchase is part of a plan to start production of fibre-based materials to serve both Indian and export markets of the FiberComposites segment.

Ahlstrom has also been investing in capacity expansions back in Finland. Over the last few years it has expanded the capacity of its glassfibre tissue and mat line at the Karhula plant. Another building and new machinery has been added at the Mikkeli speciality reinforcements plant where produces include multiaxials, unidirectional (UD) tapes, woven rovings, Combiflow (three layers: a layer of binderless chopped strand mat on either side of a porous elastic layer in the middle), stitched mats, combination products (eg. woven roving stitched to a layer of chopped fibres), and products tailored for infusion and resin transfer moulding (RTM) processes. The primary markets for these products are the wind energy, boat building and transportation industries.

Around 95% of the Mikkeli plant's production is exported, mainly to other European countries.Growth plans

These ongoing investments in the Glass Nonwovens business are part of the Ahlstrom group's growth targets. This increase is expected to come from organic growth as well as by acquisitions. Investments are targeted to expand business in fast growing markets and to serve customers globally. The company's strategy also focuses on high performance fibre-based materials and involves the divestment of non-core assets and under-performing units.

Ahlstrom specialises in high performance fibre-based materials. The Finnish group's nonwovens and speciality papers are used in a large variety of everyday products, including filters, wipes, flooring, labels, and tapes. It had net sales of €1.6 billion in 2006. Over 60% of its net sales are in Europe; North America accounts for around 20% and less than 10% are in Asia Pacific. Ahlstrom reports its operations in two segments: FiberComposites; and Specialty Papers. FiberComposites is made up of the three business areas Nonwovens, Filtration and Glass Nonwovens. Specialty Papers comprises the two business areas of Release & Label Papers, and Technical Papers. The Glass Nonwovens business produces glass fibre reinforcements, speciality glass reinforcements and glass tissue. Ahlstrom estimates that the volume of the overall market for the FiberComposites segment is currently growing at a rate of approximately 6-7% a year. The overall market for Specialty Papers is increaseing at an average annual rate of 3-4%. Ahlstrom has 5700 employees and sales offices and production facilities in over 20 countries. The company has been listed on the Helsinki Stock Exchange since March 2006. |

Group turnover is expected to reach €2.2 billion next year, up from around €1.6 billion in 2006.

For the Glass Nonwovens business, this also means high growth targets.

"The objective is to double sales in the next three years,” Dan Jönsas told Reinforced Plastics.

In terms of turnover, the Glass Nonwovens business is already one of the leading speciality reinforcement suppliers worldwide, he says.