No spectator could miss the message of peace suffusing every aspect of the Beijing Olympics this August, a spectacular event in every sense. Underlying the keen focus on the scoreboards for every race was a keen focus on engineered materials in the equipment used by these elite athletes. While participants raced for their countries in the spirit of peace, within each competitor's heart is always the desire to lead and win every contest in the ultimate spirit of pace.

Beyond an athlete's natural talent and strenuous training, equipment plays a crucial role in most competitive sports. Advanced composites in this equipment can complement athletic performance through strength, stiffness, complex geometry, reduced weight, damping, aerodynamics and durability. Athletes also attest to the unique ‘feel' of engineered composites, whether in racquet, club, bicycle, bat, blade, board or boat.

Dinghy sails to silver

20 years ago this year, the women's two-person 470 class dinghy races debuted in the Olympic games. These light, quick sailboats − 4.7 m long, weight of 119.7 kg, mast height of 6.7 m, volume of three sails at 25.7 m2 – utilise a nearly vertical centreboard and rudder and respond immediately to a sailor's body movement. As such, the two-person team must work with heightened synergy, especially since the crew sailor has to be downright acrobatic in terms of leveraging her body weight to keep the boat level in all conditions.

The 470 Class races at this year's summer Olympics were held off the coast of Qingdao. Working with the Dutch Olympic Committee and Dutch Sports Federation, DSM Composite Resins of Schaffhausen, Switzerland, developed a special polyester resin and glass fibre/polyester laminate utilising Neogel Eco gel-coat. The laminate with low-VOC gel-oat was hand layed up in a prototype 470 dinghy and tested for a year by the 470 team representing the Netherlands, Marcelien De Koning and Lobke Berkhout. The edge these materials gave the boat was extra stiffness (120%), reduced weight (2.5% and within Olympic weight minimum standard), and enhanced strength (200%).

Most important, perhaps, the composite afforded a perfectly moulded hull shape that is very stable in the water. The extra stiffness makes the hull less prone to energy loss from hull bending in the action of the short waves characteristic of Qingdao coastal waters. Based on the prototype, the Dutch sailors lauded the boat for its speed and handleability.

A DSM spokesperson tells Reinforced Plastics that the laminate for the dinghy is based on DSM's experience in supplying materials for composite wind turbine blades, and is about three to six layers thick (2-4 mm). The liquid polyester was formulated for optimum adhesion, and wet out of the thinner E-glass fibres occurs in the mould. The lay-up process for the boat raced in China is called ‘cold curing.’ Italian boat manufacturer Nautivela has adopted the new materials and build-up as a new standard for its 470 class sailboats.

This year's 470 class Olympic sailing contest saw the Dutch and Australian women's teams finishing neck and neck throughout the ten trials, both earning single digit finishes among 19 teams. On 18 August, however, Australia edged out the Netherlands in the zig zag around marker buoys, taking first place gold with 43 total points. Still, the Netherlands' sailors garnered second place and the silver medal with 53 points, coming in just behind Australia's fleet pace of 20.23 minutes over the regatta's final course.

Hybrid golf shaft

From the coastal waters of China to the North Sea shore in Scotland, composites travel the globe in premium sports applications. It is international parlance that the go to player on any sports team is the one with a record for making exceptional scores. At last year's British Open golf championship at Carnoustie Links, the first Irishman to win the tournament in 60 years used a go to hybrid utility club with a Helical Tour shaft designed by Hybrex Golf Inc of Tempe, Arizona, USA. In the four-shot playoff, Padraig Harrington made his game on three of the holes with the utility club for both tee shots and long approaches. In doing so, he won his first major championship and became the Number 6 ranked golfer in the world.

Howard Lindsay, Hybrex's CEO, makes the point that Harrington's choice of the hybrid club with the Helix Tour shaft demonstrated exactly what this unique carbon fibre/epoxy and titanium materials mix is designed for: critical accuracy and distance control. ‘Hybrid' in this instance has a dual meaning: it represents a golf club category incorporating the weight/torque properties of both heavy iron shafts and lighter weight woods (which may in fact be composite). A pro golfer using a hybrid club with a Hybrex shaft can bridge the accuracy and distance control properties found in a 130 g iron and a 70 g driver. From a materials standpoint, the truly innovative hybridisation of advanced carbon fibre composite with titanium allows Hybrex to engineer the best properties of each material into the low torque, linear weight progressed shaft.

Energy management is the ultimate advantage realised in Hybrex golf shafts. The carbon fibre/epoxy and metal elements are complementary in dissipating or damping lateral energy, including angular oscillations on the downswing and off-axis rotational distortion upon and during impact with the ball. The Helix Tour shafts are ultra low-torque, meaning they have high torsional stiffness from the titanium but are easier to swing as a result of the damping and reduced weight provided by the carbon fibre/epoxy.

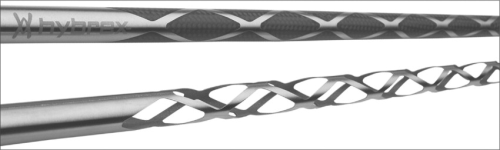

Key to achieving this high-tech merger of materials and performance are two patented technologies – BiFusion and ExoGrid. Lindsay explains that ExoGrid technology creates an exoskeleton of titanium (or other base metal), up to a third of which is laser machined away. The resulting helical pattern greatly enhances the torsional stiffness of the club action as well as the shaft's bonus aesthetics.

Within this external metal sleeve, a table rolled high-modulus carbon fibre/epoxy sleeve is moulded under 100 psi pressure at 121-148°C. This process organically fuses the two materials. Lindsay emphasises that “this is not a mechanical weld of two dissimilar materials,” but a unique adhesion process. He estimates that it takes about 40 minutes to make a single shaft, and states that a special film adhesive “is the pacing item in our cure profile.” This adhesive, along with the visibility of both materials within the ExoGrid geometry, eliminates the ‘blind bond’ encountered in conventional adhesion of two solid tubes. Also, concentricity anomalies in wall thickness that occur at the tip of a conventionally manufactured composite shaft are eliminated, which enhances consistency.

This year, Hybrex had made some significant changes in its Helix Tour shafts.

“We have added flexibility by reducing the thickness and diameter of the titanium exoskeleton overall, and in the concentration of titanium in the shaft mid-section. Also, we have increased the amount of carbon fibre in the shaft tip and are now constructing the butt section entirely in carbon fibre/epoxy rather than titanium,” Lindsay reports. “Our first generation 90 g shafts were 75% titanium and are now at 35% in the shaft tip.”

Hybrex has also shifted away from supplying hybrid category shafts to full club category service, starting with drivers.

“Premium golf shafts live or die on drivers,” Lindsay claims. “Drivers are the Holy Grail of the premium market segment, and we have 35 pros playing our Helix Tour shafts now, including the new driver shafts.”

The new driver shafts come in different flexes: S, X, XX. These options for getting the most desired feel and best chance at directing a club's sweet spot to a golfer's advantage aren't inexpensive.

“Ours is not a commodity mindset,” Lindsay concludes. “When you want the best technology partner in a golf shaft, it will likely not be the cheapest.”

Hybrex Golf Inc is a subsidiary of VyaTek Sports, which Lindsay founded in 1999 after 10 years of building composite rocket motors at Hercules and a stint with a defence contractor. To date, VyaTek has applied its ExoGrid and BiFusion composite technologies in golf clubs, tennis racquets, baseball bats, bicycle components, sports wheelchairs, and lacrosse stick handles. One of its sports OEM customers will be introducing a high-end curling stick by year's end using the VyaTek exclusive composites technologies.

Bicycle world

The CSC team cyclists competing in Beijing won at all three medal levels in various events on bicycles featuring advanced composite components. The components are manufactured by 3T Design Ltd of Madone, Italy, and also made news on bikes ridden by winners in 2008 Tour de France race classifications. On these championship bicycles, 3T's products include the VENTUS aerobar, ERGOSUM handlebars, ARX stems and FUNDA aero fork.

Richard McAinsh, 3T's Technical Director, explains that for race-calibre bicycle components, the goal in using carbon fibre composites is to build in strength and stiffness properties that can handle complex deflections under load, including material elasticity and yield stress levels, while also delivering the least possible mass. It's no exaggeration that world team cyclists can lift their bikes with one finger, they're that light weight. Earlier this year, McAinsh led 3T in tooling up to accomplish these goals with a high-powered computer aided engineering platform that includes software capability for new product design (Dassault's CATIA V5), finite element analysis (FEA from NEi Nestran) and manufacturing optimisation (VISTAGY'S FiberSIM).

“This platform gives us the ability to examine FEA structural and dynamic performance through a fast, iterative development process, and the gigabyte calculation capacity to optimise FiberSIM's control of the strains in every material ply of a component's lay-up. Overall, these tools increase the likelihood that a prototype, designed to engineering standards at the aerospace and professional race car level, will deliver desired performance the first time out,” McAinsh says.

3T actually introduced its first sports products in aluminium, including its bullhorn-shaped signature handlebars in 1975. McAinsh has brought the company into the advanced composites materials and engineering realm based on his 15 years of experience in building Ferrari's Formula 1 race cars. He believes cycle components are “no less safety critical than the suspension of an F1 car.” In addition to the software-rich engineering applied to 3T's bicycle parts, they endure rigorous exposure in test rigs and by zealous pro riders on roads and tracks, “where crashes and spills are an everyday occurrence in testing these components to real-world destruction,” McAinsh claims.

The step change McAinsh seeks in composite design must be working: 3T offers the lightest, fastest carbon fibre/epoxy racing aerobar (850 g) on the planet, the VENTUS LTD, with an integrated stem and tiny brake levers to maximise aerodynamics. The OEM's ROTUNDO variable-thickness composite dropbar capitalises upon 3T's signature round drop bend, a tight curvature that allows a rider to adjust lever orientation over a wide range of angles without significant hand movement. For both racing and recreational bikes, FUNDA composite forks come in 650 and 700 c lengths weighing 325 g or 375 g. 3T's composite seat post comes in 27.2 cm and 31.6 cm diameter, weighs 130 g and features a two-bolt clamp for adjustability. At the ultralight weight of 118 g, the ARX composite stem makes the frame connection between fork and handlebar. 3T has designed the ARX with titanium clamps.

McAinsh points out that 3T chose not to wrap an aluminium stem with carbon fibre but rather design the ARX entirely from carbon fibre/epoxy, with alloy inserts for threads and shaping.

“Luckily, my F1 experience with exactly this challenge in attaching the engine mounting onto a composite tub stood us in good stead!”

Hot out of this year's Eurobike conference concluded the first week in September, component OEM Asia Seiko of Taichung County, Taiwan, debuted its Fight Weapon bicycle frame made with woven, large tow carbon fibre in TeXtreme fabric and TeXero dry unidirectional (UD) tape from Oxeon AB, Sweden. Andreas Josefsson, Vice President of Oxeon, reports that his company's woven materials have reduced the weight of the bike frame from 880 g when made with small or intermediate tow in fabric and tape, to 770 g. The Oxeon materials are complementary in the frame; the UD tape provides flexibility in manipulation of fibre orientation to resist impact and the fabric allows for custom design of torsional stiffness.

“TeXtreme exhibits a small degree of crimp but can achieve properties close to that of a conventional unidirectional cross-ply fabric with less labour time,” Josefsson says.

He adds that customers in the sports industry “tend to act quickly and are not hesitant to try innovation and, if it works, to adapt their products.” They also like the ‘tricked out’ look of the larger carbon fibre squares in Oxeon's weave patterns.

Over the past two years, Oxeon has segued from prototype scale manufacturing to an industrialised process, and the sports market is key for the company. Fabrics are available in areal weights of 80-200 g/m2, with tapes in the 40-100 g/m2 range. Josefsson suggests overall product evaluation is underway to net more efficiency, by possibly increasing higher and intermediate modulus fibres in the fabric weave, lowering material areal weight to increase fibre spreading, and reducing the amount of stabilisation material.

Surfin' safari in nanoland

If there's a buzzword in the composites industry today, it has ‘nano’ in it, whether nanomaterials, nanocomposites, nanoparticles or nanopreg. High-purity carbon nanotubes or CNTs (usually multiwalled) are at the heart of this reinforcement revolution in the one-billionths of a metre realm, and bring both pros and cons to sports equipment.

The pros of adding CNTs to surfboard glass/epoxy laminate, according to Desi Banatao of Entropy Sports, a surfboard maker in Santa Monica, California, USA, are a dynamic boost in mechanical properties. For athletes subjecting their equipment to the slam of breaking waves, ocean rocks and sand, this translates to extreme toughness and extended board life. Products can be made lighter as well, since lower loadings of CNT are required than other fillers.

Over a year's time in 2006 and 2007, Entropy Sports worked with Nanoledge, of Boucherville, Quebec, a company that added CNTs (Baytubes supplied by Bayer MaterialScience) into the surfboard OEM's epoxy system. The resulting prototype short board (6.8 ft long) was constructed through hand lay-up and vacuum bag cure. The board's core is expanded polystyrene, and three layers of fibreglass protect the board's surface exterior (two plies on top, one on the bottom).

Sports retailers know that the purchase of expensive sports equipment involves emotion, so a product's appearance is designed to elicit that response. Surfboards tend to present themselves in bright colours and cutting-edge graphics. However, the CNT reinforcement in this prototype board limited surface colour to pitch black, which can obviously draw in considerable heat on a sunny day at the beach. Banatao says Entropy makes several other CNT reinforced boards, along with its own line of Bio Boards, which utilise an environmentally friendly pine-based epoxy as well as hybrid reinforcement with glass and natural fibres such as hemp, flax, and bamboo. “We are the prototyping kings of surfboards!”, he jests, but takes customer satisfaction and eco-responsibility seriously

For its part, Nanoledge offers its NANO IN RES MASTER SERIES resins, which can be filled with CNTs, nanoclays and nanosilica using proprietary dispersion technology. The resins have reportedly demonstrated improved impact resistance of 50-100% and 2.5 times greater overall strength, toughness, flexibility, chemical resistance, compression and fatigue resistance, and conductivity properties. The CNT-filled resins have also been tested in skis, bats and arrow shafts.

An even tougher environment for composite sports boards can be found in the skateboard arena. Hanging ten over concrete and metal street courses, “those athletes really torture test their boards,” observes Russell Belden, Business Development Manager for Zyvex Performance Materials (ZPM) in Columbus, Ohio, USA. ZPM actually engineers the dispersion of CNTs into existing resin matrices, using its trademarked Kentera surface treatment to keep the CNT side walls from clumping together, and non-covalently enhances the CNT/resin bond. This molecular additive service makes up about 20% of ZPM's business, and the matrices may be thermoset, thermoplastic, metal or ceramic. In 2009, the company will begin selling its own commercial nanomaterials: Epovex CNT reinforced epoxy and Aerovex CNT/epoxy prepreg.

Belden tells Reinforced Plastics that Insect Skateboards will commercially launch boards on 1 October that are made with Aerovex prepreg laminated over birch core. The high shear strength of the wood with the ultra-high tensile/compressive strength of the CNTs in light weight boards will also provide a 50% price reduction compared to skateboards with conventional carbon fibre/epoxy laminate in the deck. Insect reports developing new tooling that will allow for rapid production of nanotech blanks, and use of CNC machining to decrease shaping time. Accuracy can be achieved in the deck laminate to 3/1000ths of an inch; Belden says cure factors for the CNT laminate deck are 128°C at under 30 psi.

ZPM is no stranger to sports product applications, having worked extensively with Easton Sports in creating CNT composites for bats, bicycle components, hockey stick blades, and with Aldila in golf shafts. Belden notes that CNT composites give baseball bats better weight balance along the bat's length, and twice the durability of traditional composite materials. Easton says it gets about 150 GPa tensile strength from the high quality dispersion of the 10-20 microns long CNTs. The ‘sweet spot’ on a club or blade can also be extended using molecular CNT engineering.

Belden says testing of the Aerovex prepreg has shown a 35% improvement in mechanical properties, and the Epovex epoxies can be wetted out with glass, although the final product look will be graphitic black. High-end sports equipment comprises about 10% of ZPM's annual business; other application areas include aerospace, marine, and defence. Among the key nanotube suppliers with whom ZPM works is Arkema, manufacturer of Graphistrength multi-wall CNTs.

Back to the beach with SMC

Though sheet moulding compound (SMC) may not immediately come to mind as a high-performance material, it gains that status in a carbon fibre and nanoparticulate-reinforced hybrid polyester/polyurethane matrix. This composite is compression moulded into hull, liner and deck components for Yamaha Watercraft Group of Kennesaw, Georgia, USA, in several of its 2008 WaveRunner personal watercraft.

Using resin supplied by Reichhold Inc, Research Triangle Park, North Carolina, USA, and SMC formulation from Interplastic Corp, St. Paul, Minnesota, USA, Yamaha calls its special SMC recipe NanoXcel.

“Yamaha is the only OEM that has successfully developed an SMC material that is strong enough to meet the extreme structural demands of personal watercraft,” states Harold Wallace, Product Engineer for Yamaha Motor Manufacturing Corp.

He relates that Yamaha originally selected standard SMC in the late 1980s, even though it was heavier than other reinforced plastics, at a density of 1.9 g/cm3, because compression moulding offered an environmentally sound processing method. Wallace says Yamaha was already moulding small plastic parts but nothing as large or performance critical as the WaveRunner components.

Customers kept requesting faster, more powerful vehicles, and Yamaha made requests of many different compounders for lower density SMC recipes. When the call went unanswered, “our own staff embarked on a mission to reduce the weight of the SMC, and we were able to do so, to a density of 1.7 g/cm3. This became our competitive edge through the 1990s.” By 2001, the company wanted further SMC weight reductions.

“We were looking for a way to replace the heavy calcium carbonate filler with a lighter material.”

When Yamaha met with staff from Interplastic, they found a partner that Wallace says “showed promise, capability, and a desire to develop a lower density SMC formulation that would be capable of meeting all the personal watercraft market requirements while surpassing all of Yamaha's environmental concerns, processing issues, and quality requirements.”

“This 1.45 g/cm3 density nanoclay-filled SMC became NanoXcel, without a major cost run up or change in our manufacturing process,” Wallace recalls.

The hybrid resin provides the flexibility and toughness of polyurethane and the high strength/stiffness and temperature resistance of polyester, and is compatible with the nanoclay.

Besides being able to mould NanoXcel with 10-15% less tonnage and lower temperature than traditional SMC, Yamaha has been able to mould its 2008 FX SHO and HO WaveRunner models in the 2007 HO WaveRunner mould without modification. Customers have provided feedback on this year's models in terms of improved acceleration, top speed, durability, fuel savings, and responsiveness.

Wallace admits the NanoXcel material price dictates that “we reserve it for the high-performance and top-of-the-line models. We are already seeing racers gravitate toward our production units, and the NanoXcel material is an important reason why they are choosing Yamaha.”

Terry Van Hyfte, Technical Director for Molding Products, a subsidiary of Interplastic Corp and compounder of NanoXcel SMC, agrees with Wallace.

“At the high-end of personal watercraft, speed is key. When we began working with them to formulate NanoXcel, Yamaha was coming up with a new engine, but also wanted to reduce the overall vehicle weight and improve the aerodynamics with a smoother surface material. The key components still had to meet Class A surface finish without the use of glass spheres in the SMC, as well as deliver the ruggedness needed for impact resistance. This has been our first experience with a nanomaterial and also the most complicated formulation we've developed to date.”

He says that Yamaha routinely demonstrates its definition of ruggedness by taking a sledge hammer to the WaveRunner sides during durability testing.

When it comes to nanocomposites, Van Hyfte believes “there's no book you can read on the topic to come up with a specific compounding recipe, so we used the science of trial and error in order to determine optimum thickening and maturation time when adding the nanoclay into the SMC formulation.” The nano filler allows more room for pigment, which is important since Yamaha wanted a particular degree of black in the WaveRunner exterior.

Fluid market

Do these premium applications indicate that the spirit of pace is winning more growth for composites in the sports equipment market? An analyst with Composite Market Reports suggests that, while overall demand for carbon fibre in this market is on the rise, this is a mature market that is directly affected by consumer spending. In the struggling US economy, and in Europe as well, the feel good factor of such high-end sports equipment purchases will likely see a decline. Better news on the horizon: the analyst thinks “maybe look for an uptick in this market in late 2010.”

In June, the National Sporting Goods Association, Mount Prospect, Illinois, USA, reported retail sales for sporting goods last year (including footwear and clothing) reached €38.1 billion ($53.5 billion) and are expected to be flat (at $53.4 billion) this year. In 2007, the largest segment for consumer equipment purchases was in golf, followed closely by fishing.

For anyone who doubts the far-reaching nature of advanced composites in sports equipment or the ardency of sports enthusiasm, here's a slightly less publicised fact from Beijing's summer games: 600 alternate fuelled vehicles (AFVs) were crucial in China for transporting athletes and spectators alike in the spirit of pace to and from the busy, multiple event sites. Some of these AFVs were running on natural gas, some on electricity, some hybrids, and some featured hydrogen fuel cell propulsion. Without advanced composites in the pressurised fuel storage tanks, in the bipolar fuel cell plates, and even filtering out smog to the engine, the AFVs could not have provided such Olympian service.