The viscous adhesives and bonding compounds used in pumping and metering can pose many challenges for the reinforced plastics used in the aerospace, automotive and renewable energy industries.

For years, pumps and flow meters have been used as important component in all aspects in production from bulk transfer to the final application. However, with ongoing breakthroughs in technology, more advanced pumps and flow meters are now being used to provide a far more measured approach. And covering far more complicated fluids such as special resins (with carbon fibers) are plastic ingredients and complex adhesives which help manufacturers meet the demand for faster, lighter, stronger, quieter and more fuel-efficient products.

Moving thicker viscous fluids can pose a number of challenges for engineers. Firstly, their thick and sticky consistency means they can create large system pressure losses when pumped through pipework and fittings (valves, heat-exchangers etc). A simple 90-degree bend will again add yet another pressure loss and if there’s a quantity of these, the numbers can soon stack up. So it’s essential that a pump is capable of generating enough pressure to allow the viscous fluids to flow freely at the desired flow rate as required especially when part of an automated adhesive system.

Secondly, while in the pipework, adhesives, glues and resin components can have a tendency to harden, especially if they come in contact with air or changes in temperature. If the fluid is sensitive to temperature it can change the fluid’s dynamics such that it becomes either runnier and less thick, or harder and in the process of setting.

Given these challenges, what type of pump and flow meter works best for these kinds of viscous fluids? ‘In our experience, it is best to avoid standard or traditional gear pumps and flow meters as they tend to be large, sometimes expensive, primarily designed for other applications and markets and therefore often unreliable due to their very low output frequencies which can make them difficult to control,’ said Andrew Biggs, from UK Flowtechnik. ‘Instead, our pump of choice is the German-made Beinlich, which has a range of positive displacement pumps, both gear and progressive cavity, specifically designed to deal with both high and low viscosity, thereby making the pumping of thick and sticky fluids much easier.’

So what makes the Beinlich so superior, in his view? ‘To start with, Beinlich’s pumps operate at a constant flow and pressure at a given viscosity with a high volumetric efficiency, so they are able to be extremely accurate and with a repeatable output and are therefore suitable for dispensing and dosing, given the flow rate will remain proportional to the speed. The pump’s innovative design can also cope with a wide range of viscosities, but as with a majority of positive displacement pumps are ideally suited to thicker fluids as reducing internal ‘slippage’ as mentioned, the volumetric efficiency actually increases improving its accuracy.

Adds UK Flowtechnik’s James Lees: ‘Finally, as is generally well known, a bi-product of pumping thicker fluids is the possibility of high system pressures within pipework and fittings, but again the Beinlich pump is more than apt to cope with pressures up to 200 bar.’

A spot-on ratio

Typically, viscous glues and compounds (if mixed at the point of dispense) can range from one to one million centipoise (cPs), where distilled water measures at one centipoises, and more viscous liquids such as motor oil generally measure between 100 to 2,000 cPs, while extremely thick fluids such as adhesives, resins and window putty measure around 1,000,000 cPs. But whatever the viscosity, when pumping and metering, it’s essential that the chemicals and components that make up the adhesive are mixed to the correct ratio and when dispensing their singular or combined flow rate must be spot on.

Starting with the pump, that’s where the Beinlich Pump comes in, says James Lees. ‘Starting at very low flow rates of 2 millilitres per minute and rising up to 3,000 litres per minute on the external gear pumps, the Beinlich works well when used as part of on a closed-loop-control system when partnered with a flow meter. This allows engineers to check the output via the reading from the flow meter against the speed and performance of the pump, allowing them to adjust or self-regulate the flow of the adhesive, component part and hardener until the right ratio is achieved. Indeed, if the ratio of is not accurately controlled, the strength of the adhesive compound is reduced, made brittle or in the worst case does not harden at all. All of which leads to the bond failing.’

Many manufacturing processes typically use adhesives to make a range of products from very small components to large layered and bonded carbon fiber parts such as wing panels, car doors and extremely large components such as wind turbine blades. ‘As you’d expect, pumps and flow meters play a key role,’ adds James Lees. ‘Any pump used in the bonding process must have the ability to be fine-tuned, so it can dispense over a range of speeds as required.

‘And when it comes to bonding parts, it’s imperative that the right amount of resin is in the right place, so a high accuracy flow is essential. After all, no car manufacturer for example would be worth their salt if they produced a car that started to fall apart, due to inadequate bonding. Including a VSE flow meter with interpolation electronics, which produces extra signals and pluses, allows the engineer to control the variables in a more responsive way and alter the amount of adhesive that is pumped out, thereby ensuring every finished product is of the same high quality.’

And if all this wasn’t challenging enough, varying the temperature of a viscous adhesive compounds also changes its dynamics. Even turning the heat up or down by a few degrees can have a big impact potentially changing the properties of the ‘glue’. According to James Lees, the Beinlich pump comes into its own here as well, as under a closed loop control system the inclusion of a sensor in the line specifically designed to monitor temperature can also provide pump speed adjustment as required.

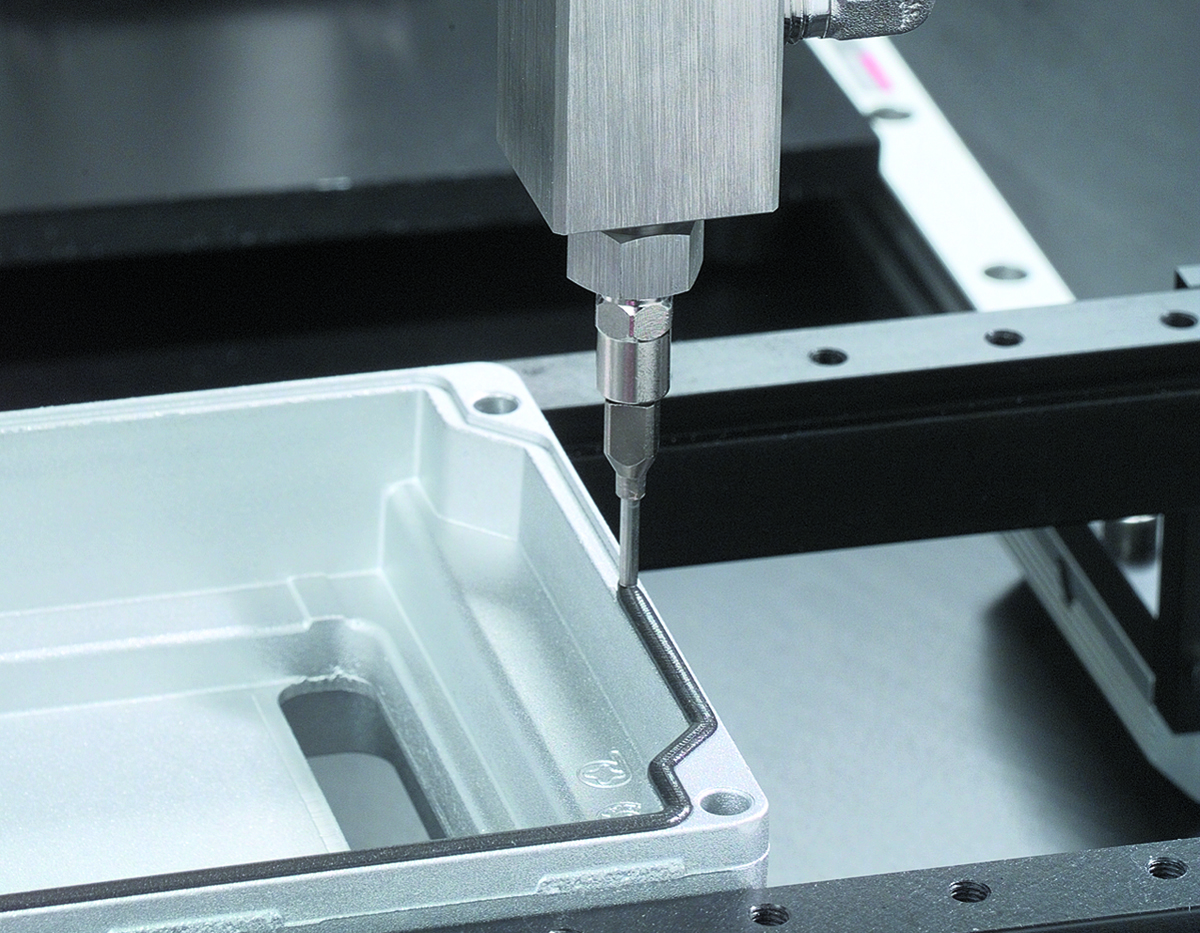

As part of an automated process and pin-point dispensing from a robotic arm, the new progressive cavity VISCO.pump adds to the range by providing a pump with no pulsations which can be easily machine mounted. The VISCO.pump has been designed for very precise dosing of fluids and pastes and is especially suitable for abrasive media with the ability for dosing and dispensing proportional to speed with an accuracy and repeatability of ± 1%. The technology of the pump is based on the volumetric principle of an endless (infinite) piston where the core components (rotor and stator) form a perfectly sealed metering chamber. The eccentric movement of the rotor allows for a low-shear motion of the fluid from one chamber to the next chamber without shearing the media. Commonly coupled to a DC geared motor, allowing for stepped controlling of the number of revolutions per minute (RPM) on a given traverse, the pump can dispense a constant bead of glue as part of an automated robotic process.

‘Yes, viscous fluids are a tricky customer at the best of time,’ Andrew Biggs ‘But our experience over 25 years has taught us that that, when it comes to pumping and metering such adhesives – be it in the aerospace, automotive or renewable energy industries – a specifically designed Beinlich pump and the VSE flowmeter, with its interpolation electronics, can help to significantly reduce the challenges they pose.’

This story is reprinted from material from UK Flowtechnik, with editorial changes made by Materials Today. The views expressed in this article do not necessarily represent those of Elsevier.